Construction sector in Nepal is changing faster than ever. Rising material prices, various code enforcement, complex urban sites, and growing expectations from developers mean that traditional manual methods are no longer enough. Contractors who rely solely on paper drawings, WhatsApp messages, and fragmented communication face frequent delays, rework, disputes, and compliance risks. The situation is even worse in the implementation of government projects. To meet modern project demands, Nepalese contractors should shift towards digital construction workflows. These workflows combine technologies such as BIM, cloud-based coordination, mobile site documentation, and modern monitoring tools. The result is improved accuracy, stronger communication, and reduced rework throughout the project lifecycle.

Figure: This AI-generated depiction of a delayed bridge project reflects the real-world challenges caused by poor coordination, rising costs, and prolonged timelines.

Moreover, many Nepalese projects suffer delays and steep cost escalations due to systemic non-technical issues. For example, a major review of national-level infrastructure projects showed that the aggregate cost of prioritized “national pride” projects jumped by over NPR 1,050 billion largely because the works were not completed within their original schedules. Factors behind such overruns frequently include weak planning and monitoring, poor inter-agency coordination, failure to secure environmental or land-clearances, and repeated design changes or scope expansions. Source: (Onlinekhabar)

Thus, especially for public or large-scale projects, moving to digital and integrated construction workflows is not just a matter of convenience or efficiency; it is an essential step toward mitigating structural inefficiencies that presently drive delays and inflate project costs.

What Digital Construction Means in Nepal?

Digital construction refers to the use of technology, structured data, and integrated workflows to manage the entire project lifecycle from planning to handover. In Nepal, digital construction refers to the use of modern tools and platforms that strengthen communication, improve documentation, minimize errors, and enable all stakeholders to work more collaboratively bringing together Clients, Contractors, Consultants, and Communities through better Coordination and Communication. This integrated approach reflects the concept of the “6 C’s,” ensuring smoother, more transparent, and more efficient project delivery.

Figure: The 6 C’s Integrated Approach: A visual framework showing how Clients, Contractors, Consultants, and Communities are connected through Coordination and Communication.

Building Information Modelling (BIM)

BIM is a digital representation of a facility’s physical and functional characteristics. It is a collaborative process where teams create, share, and manage intelligent 3D models during a project’s entire lifecycle. Unlike traditional CAD systems, BIM integrates detailed data about building components, materials, systems, and even construction schedules. This enables more accurate planning, design, construction, and long-term operation of buildings.

Figure: The BIM model of the office setup shows the selected element’s IFC material properties listed as Glass.

BIM Based Cloud Documentation

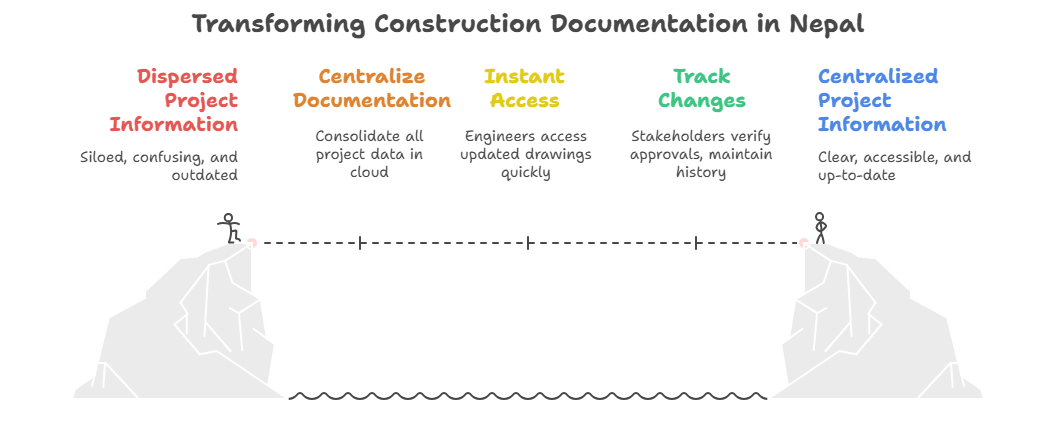

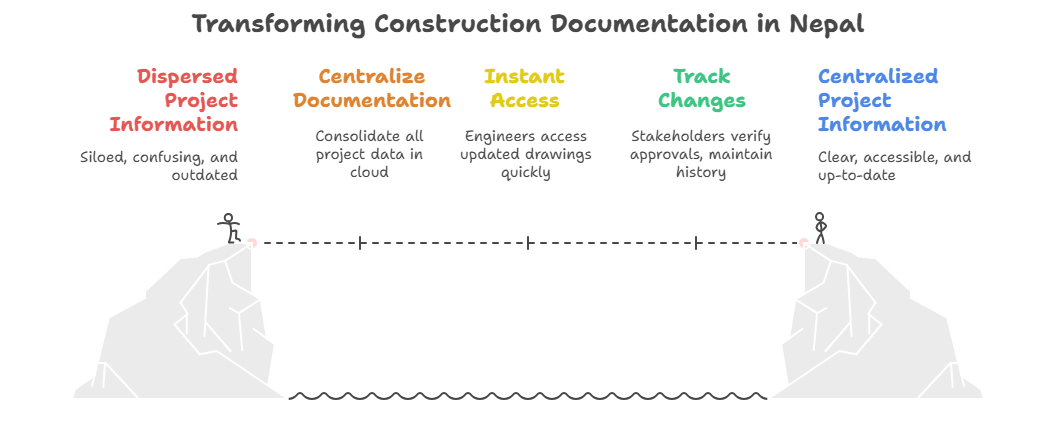

In the Nepalese construction environment, project information is often shared through messaging apps or manually printed documents. This creates confusion when multiple revisions exist. BIM based cloud documentation helps centralize all drawings, models, RFIs, photos, and daily site records in one secure location. Engineers can access updated drawings instantly, which significantly reduces miscommunication. Because cloud platforms record every update, stakeholders can track changes, verify approvals, and maintain a clear history of the project. This is especially beneficial in Nepal where construction teams are distributed across difficult terrain and rely on fast information flow.

Figure: A visualization of BIM-based cloud documentation, where project data, models, and field updates are synchronized instantly to reduce errors, strengthen coordination, and improve decision-making.

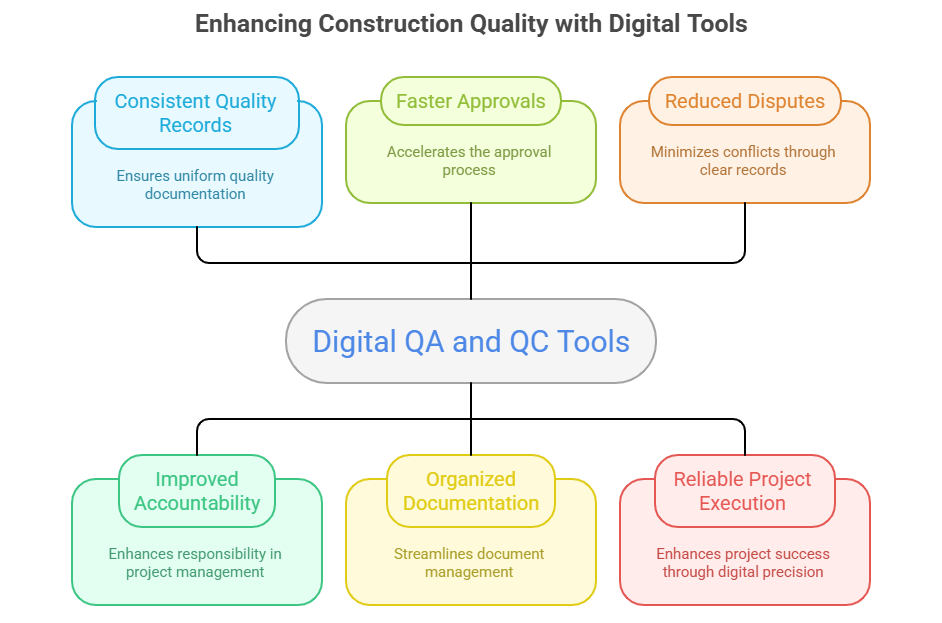

Digital Quality Assurance and Control

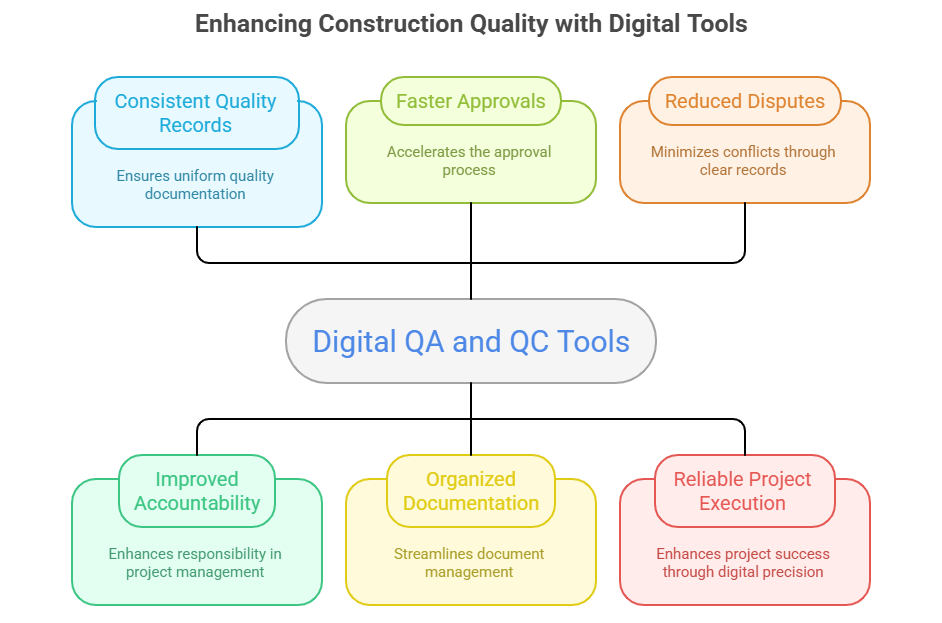

Digital QA and QC tools help contractors maintain consistent quality records. In Nepalese projects, site inspections, material tests, and approvals are often logged manually, which makes it difficult to track issues or verify compliance. Digital QA and QC systems allow engineers to record inspections using mobile devices, attach photos, and maintain timestamped logs. These records improve accountability and allow consultants to verify progress more easily. Contractors benefit from faster approvals and organized documentation during municipal verification or client reporting. This reduces disputes and ensures more reliable project execution.

Figure: Using digital QA/QC workflows, teams capture site data instantly, identify issues early, and maintain consistent quality throughout the project lifecycle.

Project Dashboards and Analytics

Project dashboards give Nepalese contractors a clear view of project progress using real time data. Instead of waiting for end of week meetings or manually prepared reports, managers can see work status, manpower data, material consumption, and issue logs at any time. Dashboards help identify delays early and allow teams to take corrective actions before problems worsen. This is particularly useful for hydropower, road construction, and large building projects where progress tracking is often complex. Dashboards also provide transparency for clients, helping them understand how the project is moving without constant site visits.

What Benefits Digital Construction Brings to Nepalese Contractors

The solutions explained above provide various benefits to the workflow of Nepalese contractors. These benefits directly address challenges such as frequent design changes, communication gaps between consultants and contractors, and the difficulty of maintaining accurate on-site records. Digital construction supports more predictable project delivery and improves the coordination between all parties involved.

Reduced Rework Through Better Coordination

Rework is one of the most expensive problems facing Nepalese contractors. BIM and coordinated digital workflows help identify potential errors before work begins. This applies not only to buildings but also to hydropower tunnels, road alignments, and retaining structures. For example, clash detection can highlight when tunnel support systems conflict with MEP layouts or when a retaining wall design interferes with drainage systems. Although the examples differ across industries, the underlying benefit remains the same. Contractors can resolve issues in the digital model instead of discovering them on site, which minimizes delays and reduces wasted materials.

Improved Accuracy and Faster Decision Making

In Nepal, site teams often operate in remote locations with limited communication infrastructure. Digital tools help engineers upload site photos, record issues, and review drawings immediately through mobile devices. This reduces the waiting time for consultant responses and minimizes errors caused by outdated drawings. Because all information is centralized, decision makers can access accurate data and respond quickly. In projects where timing is sensitive, such as concrete works, tunnel excavation, and road construction, faster decisions help maintain momentum and prevent unnecessary delays.

Stronger Compliance with Various Codes

Ensuring compliance with Nepalese building codes and local regulations requires proper documentation and clear inspection records. Digital workflows simplify this process by storing test reports, design changes, inspection logs, and approval documents in a structured and easily searchable format. When municipal authorities or consultants request verification, contractors can provide records without scrambling through physical files. This reduces approval delays and protects contractors during quality audits, disputes, or billing verification.

How Can Nepalese Contractors Get Started

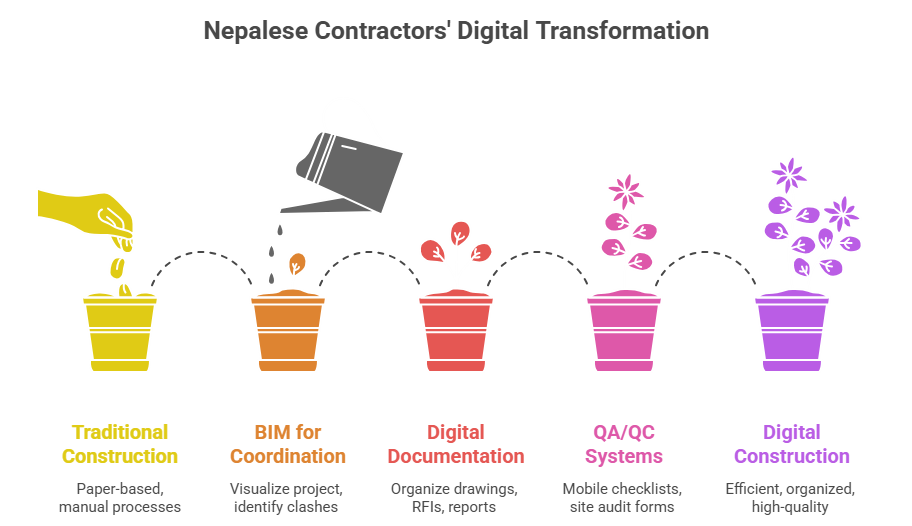

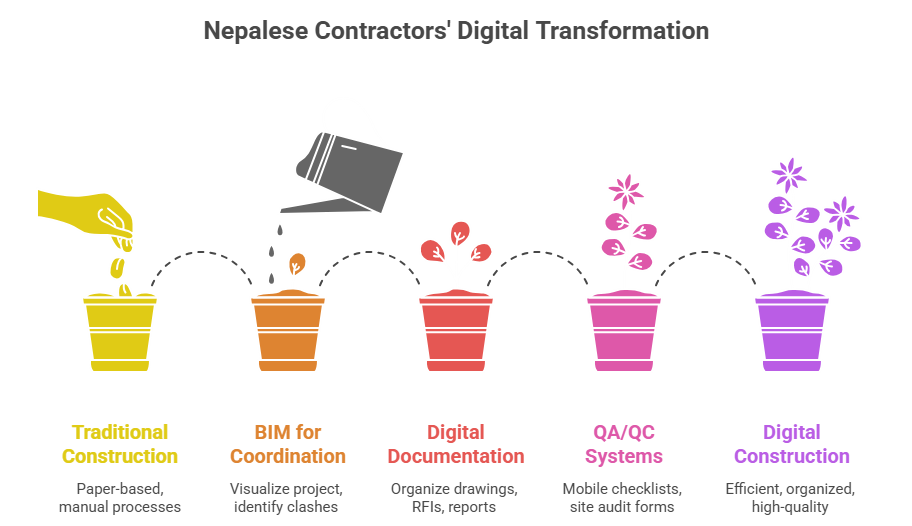

Adopting digital construction can be challenging at first, but the Forefront team is equipped with the skills and software needed to guide you smoothly through the transition from traditional to digital workflows. Nepalese contractors can start with simple tools and gradually move toward more advanced systems as the project demands increase.

Step 1: Start With BIM for Coordination

Contractors can begin by using BIM for identifying design clashes, visualizing the project, and improving coordination between disciplines. Even basic models help reduce confusion and provide a clearer understanding of the project before construction begins.

Step 2: Start With Digital Documentation

Digitizing drawings, RFIs, daily site photos, and reports creates a more organized workflow. With clear documentation, communication becomes easier and teams no longer depend on scattered screenshots or paper revisions.

Step 3: Deploy QA and QC Checklists and Site Audits

Digital QA and QC systems help maintain consistent inspection standards. Contractors can gradually introduce mobile checklists, site audit forms, and inspection logs. This creates an audit trail that supports compliance and improves the quality of final deliverables.

Figure: From BIM Coordination to cloud collaboration, this image illustrates the practical steps Nepalese contractors can take to start using BIM effectively.

How Forefront Engineering Supports Nepalese Contractors

Forefront Engineering empowers Nepalese contractors to modernize their construction practices by offering end-to-end solutions that span design, digital construction services, software implementation, and professional training. Through its comprehensive service lineup, Forefront helps organizations transition from traditional workflows to efficient, technology-driven project delivery.

Forefront provides BIM modeling and coordination, digital QA/QC systems, mobile site documentation, and custom project dashboards that give contractors real-time insights into progress, resources, and risks. The team has also supported multiple hydropower developments, including Mewa Khola and several other infrastructure projects.

Beyond project delivery, Forefront also offers specialized training programs, including BIM Fundamentals, advanced digital construction workflows, and hands-on software skill-building. With integrated services from design support to digital implementation and continuous learning, Forefront Engineering stands as a trusted partner for contractors seeking to improve quality, reduce rework, and deliver projects more efficiently in Nepal’s evolving construction landscape. Forefront also utilizes key Bentley software tools that are widely adopted in global infrastructure and construction projects. Two of the most impactful solutions for Nepalese contractors are MicroStation and SYNCHRO.

MicroStation

MicroStation is Bentley’s flagship CAD platform used for creating highly accurate 2D drawings and 3D models. It is known for its reliability and precision, especially on large and complex infrastructure projects.

Key benefits for contractors:

- Produces detailed and professional design drawings

- Handles large files smoothly without performance issues

- Supports BIM-compatible workflows

- Ensures high drafting accuracy for roads, buildings, utilities, and hydropower components

- MicroStation remains one of the most trusted design tools for engineers across Nepal.

SYNCHRO 4D (4D Construction Planning)

SYNCHRO is Bentley’s advanced 4D planning and construction management software. It links the 3D model with the project schedule, allowing teams to visualize construction sequencing step-by-step.

Key benefits for contractors:

- 4D timeline simulation showing how the project will be built.

- Better planning of site logistics and resource allocation.

- Helps identify clashes in schedule and sequencing early.

- Improves communication with clients and site teams.

- Enhances safety by visualizing site activities before execution.

If you are a Nepalese contractor and want to see how digital construction workflows such as cloud documentation, digital QA/QC, coordinated communication, and project dashboards can be applied directly to your projects, Forefront Engineering offers personalized demonstrations tailored to your needs.

Contact Us:

Phone: +977-9741803161 | +977-9741803162

Email: hello@forefronteng.com

Our team of experts is ready to assist you in integrating cutting-edge digital solutions into your projects, ensuring efficiency, safety, and sustainability.