Nepal’s steep mountains, fragile slopes, and frequent landslides make tunnels not just an option, but a necessity. From hydropower projects to highway tunnels and urban water supply systems, tunnels provide safer, shorter, and more sustainable solutions. Forefront Engineering leverages advanced digital technologies, including BIM-based Tunnel Information Modeling and real-time project monitoring, to deliver smarter, future-ready infrastructure. Supporting these efforts, the Nepal Tunneling Association (NTA) promotes safe, efficient, and sustainable tunneling practices across the country.

Types of Tunnels in Nepal

Nepal’s tunneling projects generally fall into three main categories. Transportation tunnels, such as the Nagdhunga Tunnel Project, help reduce road congestion and improve connectivity. This tunnel connects Nagdhunga in Kathmandu to Sisnekhola in Dhading, located to the west of Kathmandu. Similarly, the Siddhababa Tunnel on the Siddhartha Highway between Butwal and Tansen spans 1.126 km and is designed to enhance safety by reducing accidents and minimizing landslide risks. Hydropower tunnels, like those in the Mewa Khola Hydropower Project, are leveraging advanced digital technologies, including BIM-based modeling and real-time monitoring, to improve design accuracy, safety, and overall project efficiency. Utility tunnels support irrigation, water supply, and cable networks, playing a crucial role in both rural development and urban modernization.

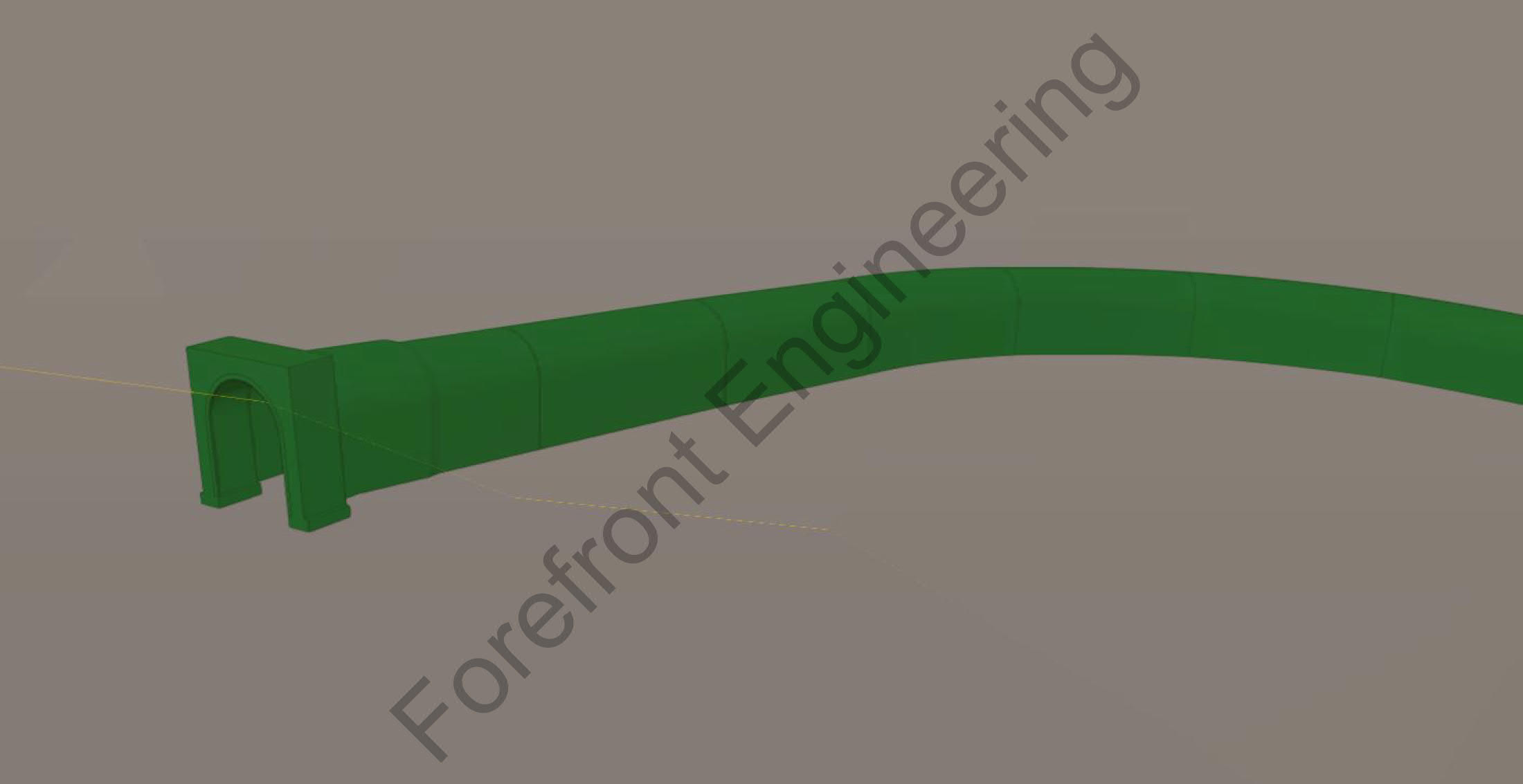

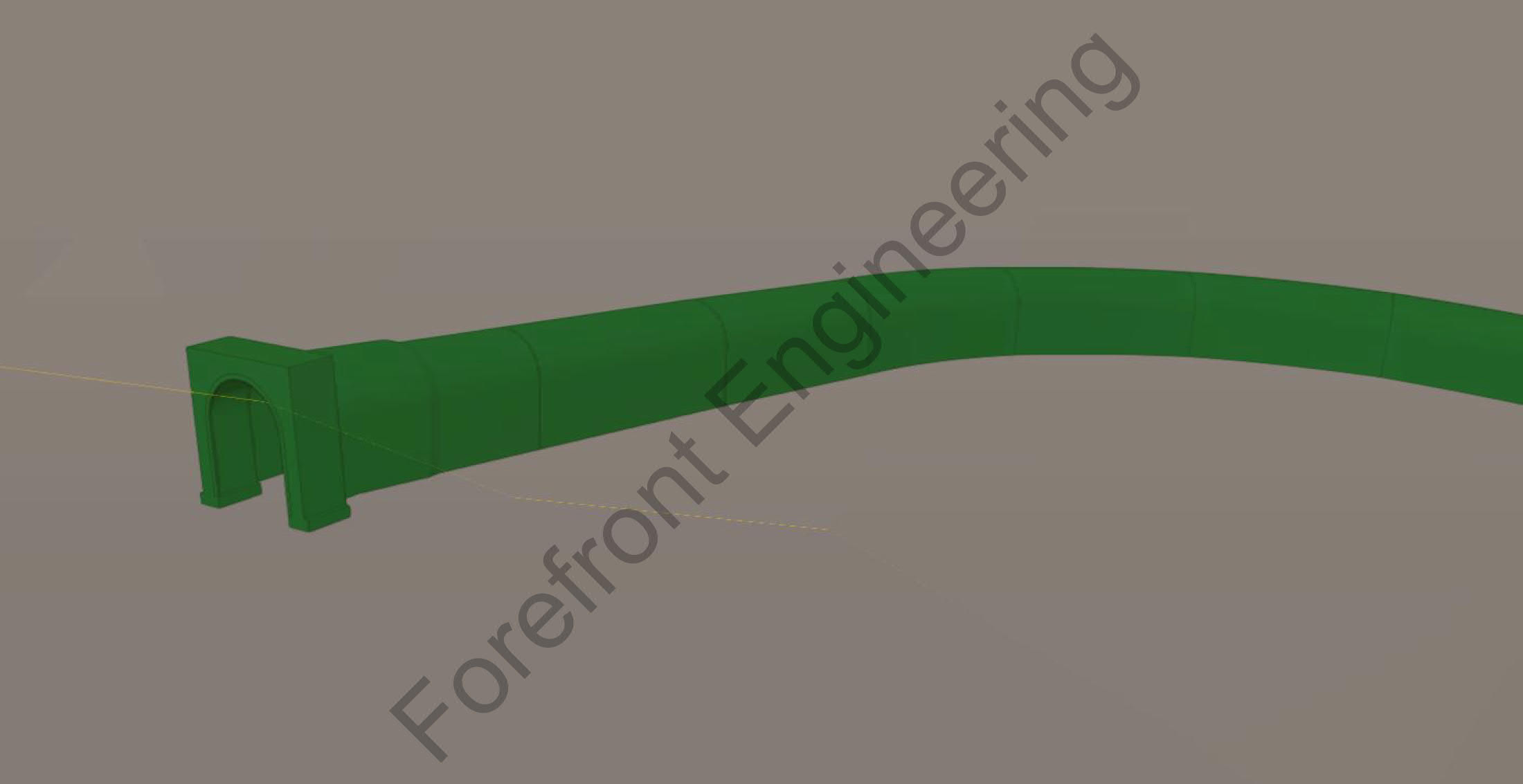

Figure: BIM Model of Mewa Khola Hydropower Tunnel | © Forefront Engineering

Tunnel Construction Techniques

Tunnel construction in Nepal employs a combination of traditional and advanced methods, chosen according to geology and project needs.

- The Drill and Blast method remains the most widely used, offering flexibility in hard rock conditions.

- The New Austrian Tunneling Method (NATM) takes advantage of the natural strength of surrounding rock, supported with shotcrete and bolts, making it adaptable to varying conditions.

- Tunnel Boring Machines (TBM), though costly, have proven effective in the Bheri Babai Diversion Project, where mechanized tunneling saved time and improved safety.

- Cut and Cover, for shallow tunnels in urban settings, the Cut and Cover method remains highly practical.

This last method is particularly relevant for Kathmandu’s urban transport projects. For example, the Koteshwor–Tinkune road improvement project, supported by JICA, has proposed the use of the Cut and Cover method to build an underpass and flyover system. This is expected to significantly reduce chronic road congestion at Koteshwor, one of the busiest intersections in the Kathmandu Valley, and demonstrates how urban tunneling solutions are increasingly shaping Nepal’s transport infrastructure.

Figure: Siddhababa Tunnel Project, image courtesy of news MyRepublica

Challenges in Nepal’s Tunneling

Despite these advances, tunnel construction in Nepal faces significant challenges. The country lies in a seismically active zone, requiring earthquake-resilient designs. High groundwater inflows often increase flooding risks during excavation. Many tunnel sites are in remote mountain regions, making logistics for heavy equipment and manpower difficult. Seasonal monsoons also disrupt construction schedules and delay progress on road projects and hydropower tunnels. By leveraging digital solutions such as BIM-based Tunnel Information Modeling, remote sensing, real-time monitoring, and data-driven planning, many of these risks can be mitigated, ensuring safer and more efficient project execution across Nepal’s growing network of highways and tunnels.

The future of Nepal’s infrastructure lies underground, with more tunnels planned for hydropower development, smart highways and urban transport systems. Projects like the Nagdhunga Tunnel, the proposed Koteshwor–Tinkune JICA road project, and upcoming flyover and underpass systems highlight how Nepal is embracing digital engineering, smart infrastructure, and sustainable tunnel construction to solve congestion and connectivity challenges.

At Forefront Engineering, we are committed to leading this transformation delivering world-class tunnel solutions that combine local expertise with global innovation. With our focus on digital project delivery, sustainable road development, and advanced tunneling techniques, we aim to shape a future where Nepal’s highways, hydropower corridors, and urban centers are connected more safely, efficiently, and sustainably than ever before.

Figure: Sunkoshi Marin Diversion Multipurpose Project, image courtesy of news MyRepublica

Digital Tools for Smarter Tunnel Design

To achieve these goals, Forefront Engineering also adopts globally recognized tunnel design and infrastructure software. Some of the most widely used tools from Bentley Systems include:

PLAXIS - for advanced geotechnical analysis and underground excavation simulations.

Structural WorkSuite - for comprehensive structural analysis and design software for tunnels and associated infrastructure. It enables engineers to model and analyze tunnel supports, linings, and other structural elements under diverse loading conditions such as soil pressure, hydrostatic loads, and seismic effects.

Civil WorkSuite - for design and modeling platform for civil infrastructure projects, including tunnels, roadways, and associated utilities. It supports 3D modeling, grading, alignment, drainage, and earthworks, making it ideal for designing tunnel portals, access roads, and interfaces with surface infrastructure.

MicroStation - for detailed 2D/3D CAD design and drafting.

ProjectWise - for digital project collaboration, document management, and real-time coordination.

In addition to these, Cesium can also be employed for 3D geospatial visualization and digital twin modeling, allowing stakeholders to interact with accurate, real-time representations of tunnels, highways, and urban infrastructure. By integrating these digital platforms, we can ensure greater accuracy, faster delivery, enhanced collaboration, and long-term resilience, helping Nepal move toward a smarter, digitally driven future of infrastructure.

If you're interested in seeing firsthand how digital tools like BIM, real-time monitoring, and 3D modeling can transform your infrastructure projects, Forefront Engineering offers personalized demonstrations tailored to your needs.

Contact Us:

Phone: +977-9741803161 | +977-9741803162

Email: hello@forefronteng.com

Our team of experts is ready to assist you in integrating cutting-edge digital solutions into your projects, ensuring efficiency, safety, and sustainability.